The plastic slip sheet is made from recycled high-density polyethylene materials. This type of material allows for greater non-tear strength

and an increased number of uses in cold and humid environments. Its advantages include longer sheet life, durable lips, ability to be stored in cold or humid environments,and that it can be handled by a roller conveyor, slip sheet lift truck, or powered unit load transportation devices.

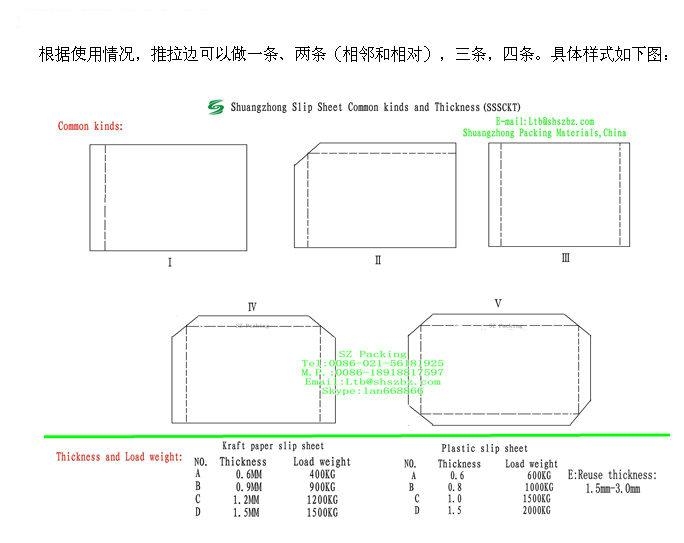

1.Single lip

The first type of slip sheet is the single lip (tab) slip sheet.With a single lip, the lip faces the narrow part of the rectangular shaped unit load and the delivery truck door. This slip sheet variation maximizes the delivery truck's space utilization and loading and unloading process productivity. Also,with a single lip, the travel path clearance is minimized as the lip faces the unit load carrier.

2.Multi-lip

The second type of slip sheet is the multi-lip slip sheet. This type of slip sheet is generally used on a container placed onto a railroad car or an ocean delivery vehicle due to the necessary loading/unloading patterns. This allows a loading device to load the slip sheet unit load from one side and an unloading device to unload the load from another side depending on the number and pattern of the remaining lips.

Common thickness and loading weight,Can customize thickness 0.6mm-3.0mm.